ABOUT US

FAQ

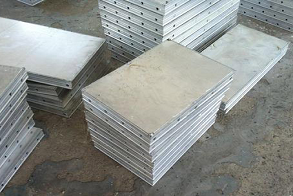

Aluminium Formwork System is a revolutionary construction Technology, which has been successfully used and developed over 30 years, for forming cast in situ reinforced concrete building structures. In this unique system, all walls, floor slabs, columns, beams, stairs, balconies, together with door and window openings are cast in situ in a single site based operation. ( Monolithic construction ). The resulting building structure is extremely strong, accurate in dimensions and tolerances, with a excellent quality of finished concrete surface and yet at the same time the Aluminium Formwork System is fast, adaptable and really cost effective.

Aluminium formwork system is a versatile solution for forming concrete structures and is very cost effective and efficient. Compared to conventional construction procedures, it provides a very excellent quality finish and evenness, while reducing floor competition cycles to 4-5 days. The lightweight panels eliminate the requirement for tower cranes, making installation both easier and safer. In addition, this formwork system is also suitable to varying structural geometries and wall heights.

Superior Concreting

Aluminium formwork can 100% turn your design into reality and achieve no-plastering concreting to lower your cost on building surface decoration.

Cost-Saving

It will create less waste on site, need less labour in operation, simplify site management and shorten your construction schedule, which all means saving budget.

Quick Turnover

With an average turnover period of 4 days/ floor, aluminium formwork can improve productivity significantly and save site cost.

High Reusability

Within its lifespan, the aluminium formwork can be reused over 250-300 times, which will save 30% budget in total, compared with timber and steel formwork

Grade– 6061-T6

Aluminium Sheet– Grade – 5052/3105 (4mmThickness)

Standard Sizes of Wall Panels– 2050x600mm , 2050x500mm & 2050x450mm,

Standard Size of Deck Panels– 1200x600mm

It generally vary from project to project. It also depend on whether internal wall are taken in concrete or masonry. A thumb rule can be applied for residential building, formwork area as 5-6 times the construction area in m2. For example 600 sqm floor area you will required approximately 3000-3600 sqm of formwork.

Load bearing capacity is approx. 60 KN/m2

The data can never be wrong, which will explain why more and more builders / contractors turn to aluminium formwork in the world.

| Technical Data | Timber Formwork | Steel Formwork | Aluminium Formwork |

| Loading Capacity (KN/㎡) | 30 | 60 | 60 |

| Reusage | 8 | 200 | 300 |

| Assemble & Dismantle | Difficult | Difficult | Easy |

| Dependence On Tower Crane | No | High | No |

| Scrap Value | Low | Middle | High |

| Maintenance Cost | Low | High | Low |

| Attrition Rate | High | Middle | Low |

| Concreting Performance | Coarse | Flat | Free of Plastering |

| Possibility of Leakage | High | Low | Low |

| Floor Cycle | 10-12 Days/Floor | 8-10 Days/Floor | 4-6 Days/Floor |

| Applications | The Whole Building | Walls | The Whole Building |

We offers a cleaning and refurbishment service to extend the life time reusability of panels. If you are interested, you can contact us for more information and details. There are various methods like chemical cleaning, high pressure water jet cleaning and sand blasting are used for removal of concrete from formwork surfaces.

- SOPs and Guidelines for Construction Sites for COVID-19 Outbreak!

A new Standard Operating Procedure [ SOP] is issued amidst the current phase of the pandemic for ‘local transmission and limited community transmission. This SOP is applicable to the current phase of COVID-19 pandemic in India (local transmission and limited community transmission). For construction sector, NAREDCO, under the guidance of Ministry of Health and Family

A new Standard Operating Procedure [ SOP] is issued amidst the current phase of the pandemic for ‘local transmission and limited community transmission. This SOP is applicable to the current phase of COVID-19 pandemic in India (local transmission and limited community transmission). For construction sector, NAREDCO, under the guidance of Ministry of Health and Family - Modern Method Of Construction- Tunnel Form

Tunnel form is a formwork system that allows the contractor to cast walls and slabs in one operation in a daily cycle. It combines the speed, quality and accuracy of factory/off-site production with the flexibility and economy of in-situ construction and is recognised as a modern method of construction (MMC). The result is a cellular

Tunnel form is a formwork system that allows the contractor to cast walls and slabs in one operation in a daily cycle. It combines the speed, quality and accuracy of factory/off-site production with the flexibility and economy of in-situ construction and is recognised as a modern method of construction (MMC). The result is a cellular - Aluminium Empowering The Green Building Revolution

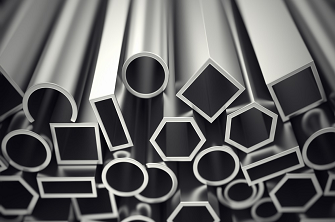

Aluminium in the Construction Industry – History Aluminium has been at the core of buildings for almost a hundred years and aluminium alloys have been applied in the construction of residential and commercial buildings. Being the second most used metal in the world, Aluminium’s role in the construction industry is very vast and diverse. The

Aluminium in the Construction Industry – History Aluminium has been at the core of buildings for almost a hundred years and aluminium alloys have been applied in the construction of residential and commercial buildings. Being the second most used metal in the world, Aluminium’s role in the construction industry is very vast and diverse. The

Blog

ADDING LIFE TO FORMWORK

We are ready and waiting to get you started on your project